PRODUCTS

NYCO® power transmission belts' structure consists of friction covers made of special synthetic rubber with high resistance to abrasion or chrome leather; nylon core layer of high tensile strength. Such structure enables the belt to have excellent comprehensive properties:

--Long service life;

--Transmission efficiency: over 98%;

--Transmission speed: over 60m/s;

--Good flexibility and directionality;

--Good dimensional stability;

--Constant friction coefficient.

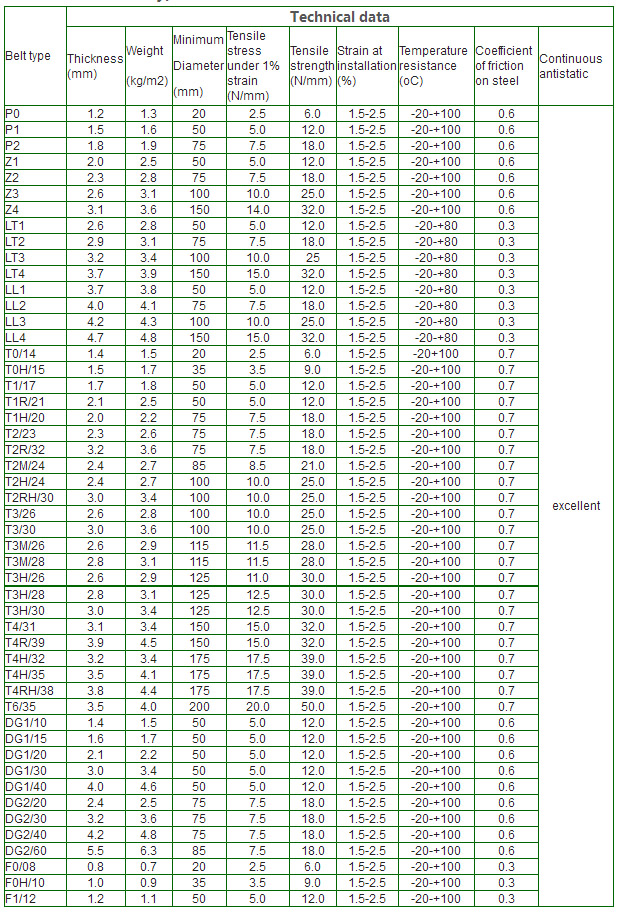

Table 2.1 shows belt types and their technical data.

Notes:

(1)Product colour codes: YE-yellow DG-dark green MG-middle green LG-light green BG-black green MB-middle blue LB-light blue DGY-dark grey LGY-light grey

(2)Applications of each series

P Series: High-efficiency power transmission belts designed for light and middle duty drive in various industries such as being used on printing machines.

Z Series: High-efficiency one-side power transmission belts designed for middle and heavy horse-power drives; being proof against oil and dust they can operate well in all conditions especially under adverse circumstances such as being used in blowers, mixers, steel rolling mills, turbine generators, marble gang saws and pumps, etc.

LT Series: Belts of one-side drive with chrome-leather surface layer designed for over-loaded and taper cone drives and drives with belt shifters in the machines such as crushers, paper-making and building machines, and blow-room machines in textile industry, etc.

LL Series: Belts of double drive with two chrome-leather surface layers suitable not only for the application areas where LT series of belts are used due to the fact that they have the same features but also for multiple and cross drives.

T Series: High-efficiency double-drive belts especially suitable for high-speed tangential drive and power transmission in textile industry such as being used on O.E. spinning frames, two-for-one twisters, draw-texturing machines, novelty twisters; they are also used in cards, drawing, roving and ring spinning frames; such belts can be used for power transmission in paper-bobbin making machines.

DG Series: High-efficiency double-drive belts designed for the drives of case-plastering, posting, packaging and circular knitting machines due to their good flexibility property.

58 Records Next 123